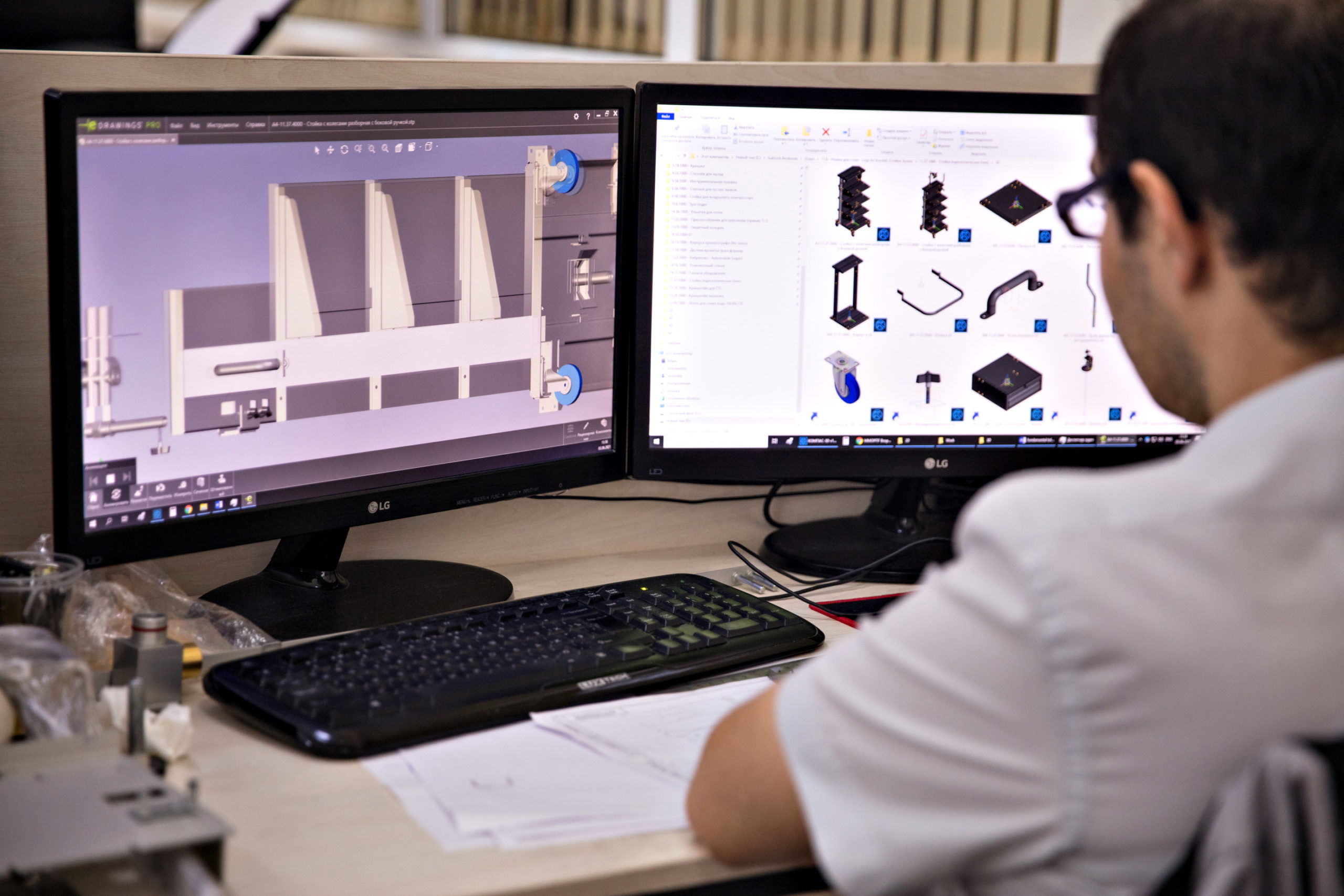

Для создания макетов будущих изделий специалисты Metal Processing используют “САПР” (комплекс программ системы автоматизированного проектирования).

Программное обеспечение САПР использует векторную графику в целях изображения объектов традиционного черчения или может также создавать растровую графику, отображающую общий вид проектируемых объектов. Тем не менее, это включает в себя больше, чем просто шаблонные формы.

САПР может использоваться для проектирования кривых и фигур в двумерном (2D) пространстве; или кривых, поверхностей и твердых тел в трехмерном (3D) пространстве.

При разработке новых проектов и подготовке чертежей мы отдаем предпочтение трём разновидностям САПР: SolidWorks, Компас, AutoCAD.

Главной целью внедрения и использования САПР в Metal Processing было снижение до минимума риска допустить погрешности при производстве изделий.

Предварительная симуляция будущего продукта позволяет заранее оценить и проверить возможные сложности его производства, а также визуально проанализировать технологию сборки и другие нюансы, что позволит принять наиболее грамотные технологические решения.

Ко всем положительным сторонам услуг по 3D-симулированию можно также отнести прозрачность реализации проектов для заказчика. Любой наш партнёр в праве получить подробную информацию о своём изделии, изучить с помощью макетов и чертежей будущее творение, а также отметить свои пожелания.

Благодаря САПР и умелым конструкторам, продукция Metal Processing отвечает мировым стандартам качества.